Shell and Tube Heat Exchanger Options Explained

Heat exchangers offer a reliable method of transferring heat between liquids and gases, without direct contact between the two mediums.

There are several classes of heat exchangers including double-tube, shell and tube, tube in tube, and plate heat exchangers

Shell and tube heat exchangers are the most common class of heat exchanger used in oil refineries and other large chemical processes, and are well-suited for higher-pressure applications.

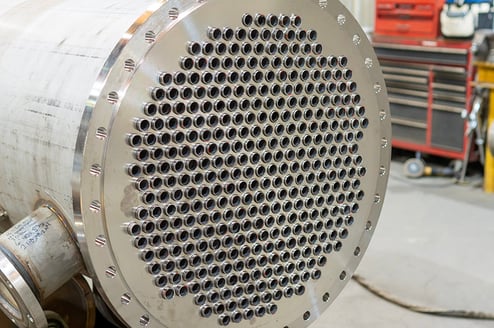

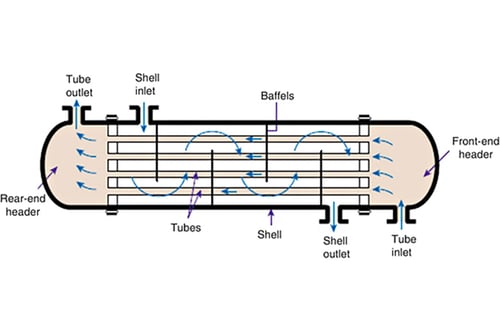

As the name implies, this type of heat exchanger consists of a shell (a large fabricated exterior pressure vessel) with a set of uniformly sized, compactly spaced tubes within its interior, referred to as a tube bundle. The tube bundle may be composed of several types of tubes, including: plain, longitudinally finned, and studded.

Shell & Tube Heat Exchanger Designs

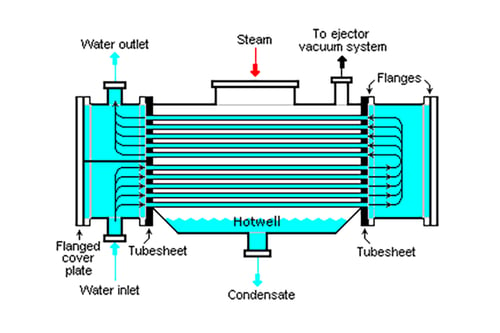

There can be many variations on the shell and tube design. Typically, the ends of each tube are connected to plenums (sometimes called water boxes) through holes in front-end 'tube sheets'.

The tubes may also be straight or bent in the shape of a U, called U-tubes. The U-tube heat exchanger is a multi-use heat exchanger that many of our clients use to support various manufacturing processes.

There are several different types of shell and tube heat exchangers that Bendel designs and fabricates for clients of varying types for varying applications, serving a wide range of industries!

How it Works

All heat exchangers operate in a similar manner, relying on established thermodynamic principals of heat transfer.

During operation, two fluids of different starting temperatures, are directed through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes, inside the shell (the shell side).

Heat is transferred from the higher temperature fluid to the the tube walls - either from tube side to shell side or vice verse - and from the tube walls to the lower temperature fluid. The fluids can be either liquids or gases on either the shell or the tube side.

In order to transfer heat most efficiently, an optimal (larger) heat transfer surface area should be used, typically leading to the use of many tubes.

One-Phase Heat Exchangers

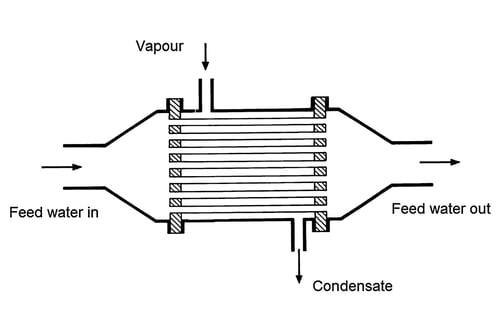

Heat exchangers with only one phase (liquid or gas) on each side can be called one-phase or single-phase heat exchangers.

Two-Phase Heat Exchangers

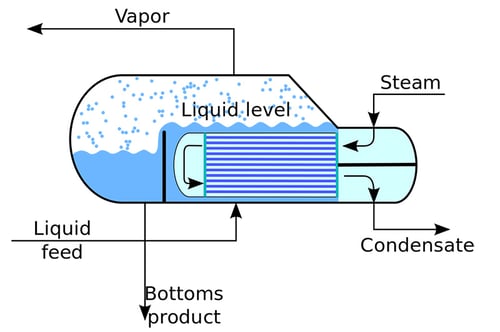

Two-phase heat exchangers can be used to heat a liquid to boil it into a gas (vapor), sometimes called boilers, or cool a vapor to condense it into a liquid (called condensers), with the phase change usually occurring on the shell side.

Boilers

Boilers in steam engine locomotives are typically large, usually cylindrically-shaped shell-and-tube heat exchangers.

Shell-and-Tube Surface Condensers

In large power plants with steam-driven turbines, shell-and-tube surface condensers are used to condense the exhaust steam exiting the turbine into condensate water which is recycled back to be turned into steam in the steam generator.

Greater Efficiency, Lower Energy Costs, Reduced GHG Emissions

Heat exchangers provide an efficient way to conserve energy by utilizing waste heat- both reducing the energy input needs of a process and reducing related GHG emissions!

Learn about our Heat Exchanger Fabrication capabilities here.